Jinggong Mould accomplished French customer's high difficulty advanced glass mould, the Chinese glass mould technology has met the world-class level

The glass mould business in Shajiabang started in 1970s, surged in 1980s, and matured in 1990s. At the moment, glass mould products are mainly exported to Russia, America, Germany, France, Australia, Japan, Belgium, Italy, Thailand and over 20 countries' advanced market.

In recent years, the Chinese glass mould industry keep innovating new technology, cultivating talents, improving quality management, and expanding market. The glass moulds made in China have an increasing impact in the international market. As the leader of glass mould industry, Jinggong undertook several high dufficulty and high precision assembling moulds business, and the products are highly recognised by customers.

The main technology covers:

the high acceptance of mould performance made from copper alloy materials and cast iron materials, the high acceptance of products presision, high acceptance of high-difficulty technology, and the high acceptance of multi-assembling mould.

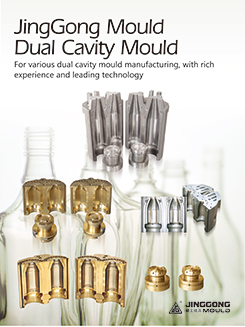

Picture 1: multiple hecteromorphism combination, the requirements of precision is high, and it is hard to process. The mould also meets the needs of advancded copper alloy materials. The product is highly recognised by our customer.

Picture 1

Picture 2: multiple positioning, surface fitting, multiple hecteromorphism combination, high requirements of precision, high standards of processing. The product is highly accepted by customer. Jinggong constantly improve the technology in producing cosmetic bottle mould, and the quality of cosmetic bottle mould is now among the world first class level.

Picture 2